Our company has established its strategic development goal of 'creating the first brand of mold inserts carbide supplier, wood tungsten carbide inserts, Insert Blanks for parting'. With this vision, we continue to innovate and cast our brand with a high degree of social responsibility. We are committed to building our core competitive capabilities in brand, R&D, technology, products, marketing and sales to achieve a new leap forward for our company. Our factory adheres to the business philosophy of 'ntegrity and win-win, people-oriented'. Since the establishment of the company, we have continuously improved product quality and expanded the sales market through technology introduction, equipment renewal, and process reform, and achieved a series of achievements. We insist on the consistency of goals and unity of thought, and emphasize relying on the teamwork spirit to require all employees to work around common development goals. The spirit of "innovation" is the inexhaustible driving force for our development, and is a necessary quality and lifelong habit for every employee.

Cemented Carbide Turning Insert Blanks for Stainless Steel:

Introduction:

As China leading manufacturer of premium cemented carbide tool blanks, we GEHM supply a vast range of ISO standard and customized CNC indexable turning insert sintered blanks from made in-house RTP powder for stainless steel turning machining, with various specifications, chipbreakers and classical grades to select.

There are many grades and surface finishes of stainless steel available depending on the environment the metal is expected to withstand. Based on the microstructure, they can be classified into four major categories, austenitic stainless steel, ferritic stainless steel, duplex stainless steel and martensitic stainless steel.

Specification:

Shape | Style | Dimension (mm) | Grade | ||||

IC | T | D | R | GU20 | |||

| CNMG120404-MA | 12.70 | 4.76 | 5.16 | 0.4 | ● | |

CNMG120408- MA | 12.70 | 4.76 | 5.16 | 0.8 | ● | ||

CNMG120412- MA | 12.70 | 4.76 | 5.16 | 1.2 | ● | ||

| TNMG160404- MA | 9.53 | 4.76 | 3.81 | 0.4 | ● | |

TNMG160408- MA | 9.53 | 4.76 | 3.81 | 0.8 | ● | ||

TNMG160412- MA | 9.53 | 4.76 | 3.81 | 1.2 | ● | ||

TNMG220404- MA | 12.70 | 4.76 | 5.16 | 0.4 | |||

TNMG220408- MA | 12.70 | 4.76 | 5.16 | 0.8 | |||

TNMG220412- MA | 12.70 | 4.76 | 5.16 | 1.2 | |||

| WNMG080404- MA | 12.70 | 4.76 | 5.16 | 0.4 | ● | |

WNMG080408- MA | 12.70 | 4.76 | 5.16 | 0.8 | ● | ||

WNMG080412- MA | 12.70 | 4.76 | 5.16 | 1.2 | ● | ||

Grade property:

Universal grade GU20 with fine grain size is widely used in stainless steel turning application to ensure good chip control and long and reliable tool life as these operations typically yield more friction and heat than many other materials

GEHM Grade | Average WC Grain Size | Industry Classification | Cobalt content | Hardness | Density | TRS(N/mm2) | Recommended coating | Application | ||||

Uncoated | CVD | PVD | Turning | Milling | Grooving | |||||||

GU20 | Fine | k20-k35 | 10.30 | 91.70 | 14.40 | 3500.00 | ● | ● | ☆ | ☆ | ☆ | |

Features:

● 100% virgin raw material

● High product consistency

● High edge-line security

● Resistance to thermal and mechanical shock

● Predictability and security

Application:

● Austenitic stainless steel machining

● Ferritic stainless steel machining

● Martensitic stainless steel machining

● Duplex stainless steel machining

Products:

Our Advantages:

● Material expertise for demanding challenges

● World first class inspection and analysis equipment like Keyence, ZEISS

● Multi-axial press capabilities

● Japan-imported HIP sintering

Our Services:

● Material inspection and approval

● Dimension inspection and approval

● Sample analysis service available

● OEM and ODM accepted

Production Process:

Our Factory:

Our Facilities:

Our Certificates:

FAQ:

Q1. How many production lines in your factory?

A: There are 4 main production lines, RTP, cutting tool blanks, wear parts and mold making.

Q2. What’s your annual output? What’s your monthly output?

A: Monthly production capacity is 4 million pcs and annually can reach 50 million pcs in total. Sufficient production capacity ensures in-time delivery of your goods.

Q3. What’s the market? Domestic or export? What percentage for export? What is the proportion?

A: Our domestic and export business are 50/50 at present.

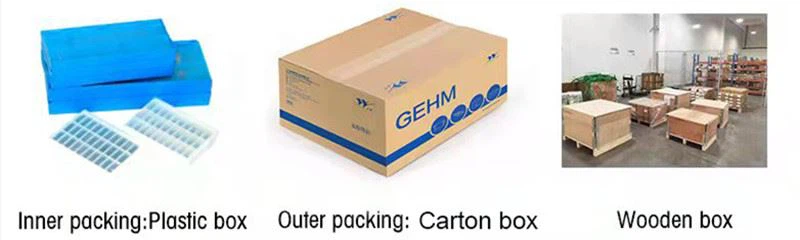

Packaging & Shipping:

Our Tungsten Carbide Insert Stainless Steel Scrap CNC Inserts is manufactured by professional personnel and tested under a comprehensive quality management system, so that its quality is completely trustworthy. We continuously operate and improve our quality management system in conjunction with our quality action plan. Today, we have a united, young, positive and excellent modern management and sales team. They carry out product research and development, design, production, sales and after-sales service with modern management concept and keen information antennae.

Hot Tags: turnning insert blanks for stainless steel, China, suppliers, manufacturers, factory, customized, tool blanks for saw tips, Cemented Carbide Flat, tungsten carbide strips 310mm, Bush Raising Valve, Positive Turnning Insert Blanks, Sleeves for Oil Pump