With its excellent quality and competitive price, our groove milling insert, Stamping Electronic Precision, Top Notch Blanks are sold in many countries and regions and won the trust of customers. We insist on green and low-carbon development and optimize the global layout of industries. After many years of operation, our company has established a perfect product system, formed a complete marketing vein through the combination of traditional channels and Internet channels, making the trade mode more abundant. We regard our employees as the most valuable asset of the company and the basis of its development. We actively adapt to the new normal of economic development, transform the development mode and cultivate innovative dynamic energy.

Flat Drill Blanks:

Introduction:

We manufacture standard and special carbide drilling insert blanks, including

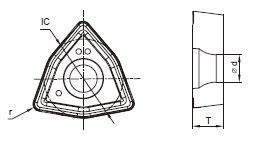

● Flat drill blanks, like SPMT, WCMT

● Spade drill blanks, like SDB blanks

● Modular drill tips in complex geometry

● Other special solid drilling blanks

With state-of-art equipment and experienced engineers, we can make 1 set of tooling per day. Generally end user will grind, hone and then coating. With dozens of press and sinter machine in house, monthly press and sinter capacity is 5,000,000 pieces.

Specification:

There are lots of flat drill blanks, such as SPMG and WCMX. Special carbide drill blanks are usually produced to customer’s drawing. Customer can send us the finish insert design as well and we will send the blank drawing with grinding stock to confirm.

Shape | Style | IC | T | D | R | GU20 |

| WCMX030208 | 5.56 | 2.38 | 2.80 | 0.8 | ● |

WCMX040208 | 6.35 | 2.38 | 3.10 | 0.8 | ● | |

WCMX050308 | 7.94 | 3.38 | 3.20 | 0.8 | ● | |

WCMX06T308 | 9.525 | 4.17 | 3.70 | 0.8 | ● | |

WCMX080412 | 12.70 | 4.96 | 4.30 | 1.2 | ● | |

| SPMG050204 | 5.56 | 2.38 | 2.40 | 0.4 | ● |

SPMG060204 | 6.35 | 2.38 | 2.60 | 0.4 | ● | |

SPMG07T308 | 7.94 | 3.97 | 2.80 | 0.8 | ● | |

SPMG090408 | 9.525 | 4.76 | 4.00 | 0.8 | ● | |

SPMG110408 | 11.11 | 4.76 | 4.40 | 0.8 | ● | |

SPMG140512 | 14.29 | 4.76 | 5.76 | 1.2 | ● |

Most Popular Grade for Flat Drill Blanks:

Grade | Application | Microstructure |

GU20 | 10% Cobalt inside, an industry-standard for round tools. Recommended for rough and LIGHT-interrupted milling. PVD-coated is recommended for longer tool life. |

|

Notes: GU20 can replace KFS64/KCM25B of Kennametal, H10F from Hyperion and HB30 from Boehlerit.

GEHM Grade | Co (%) | HRA | Hyperion | Ceratizit | Kennametal | Boehlerit | Estech | ZCC |

GU20 | 10.3 | 91.9 | H10F | CTS20D | KFS64 | HB30 | RX10 | YL10.2 |

Advantage and Features of GEHM’s Flat Drill Blanks:

● All moulds are made in house, you can design your own chip-breaker

● Traceability from powder to finished carbide drill blanks

● Multiple grades offering for different materials

Services for GEHM’s Flat Drill Blanks:

● Dimension and Grade inspection& certificates available

● Sample analysis service available, including dimensions to carbide grades analysis

● We can provide grinding service or resource if customer doesn’t have the grinding capacity right now.

Production Process of Flat Drill Blanks:

Our workshop for Flat Drill Blanks:

GEHM presence at home and abroad:

FAQ:

Q1: What kind of sintering machine do you have?

A: We have HIP sintering furnaces and vacuum sintering furnaces from Japan.

Q2: How do you make QC control? Inside or third party?

A: Usually, we do the QC control in house. If you need, third party like SGS report could be provided as well.

Q3: Do you have a privacy protection system for your customer? How do you do this?

A: From the engineering to the packing, we have a complete system to protect that. At the engineering process, we will convert your drawing into our own and then use our own drawing internally. Our plant need special permission to be visited as well and photographing is not allowed during customer’s visit.

Packaging & Shipping:

Shipping available by express such as DHL, FedEx and by air or by sea.

We continue to optimize Superior Wear Resistance Solid Carbide Plate Blank with Good Quality design and provide users with personalized services based on the market characteristics of Superior Wear Resistance Solid Carbide Plate Blank with Good Quality. The company is committed to becoming an international high-tech enterprise with a complete independent research and development system. We rely on the corporate spirit of unity, integrity, truth-seeking and innovation to achieve today's achievements step by step.

Hot Tags: flat drill blanks, China, suppliers, manufacturers, factory, customized, TCMT Inserts Blanks, face mill inserts uncoated, Cemented Carbide Studs, razor blade carbide materail, Wear Solutions for Oil Gas Industry, WNMG Insert tools