We integrate and optimize company resources through team adjustments, hoping to provide customers with professional services and reliable, high-quality Cemented Carbide Tooling Materials, carbide insert blanks producer, material carbide flats K20 as always. At present, our company has established a complete set of perfect and standardized diversified management system and the products have been well received by customers. We prioritize the protection of life and safety and the observance of compliance principles when facing all business issues. We persist in arduous entrepreneurship, unity and forge ahead to create economic benefits while not forgetting our social responsibility and mission. Our company always with full enthusiasm, in line with the enterprise tenet of innovation, development, pragmatism and integrity, is willing to sincerely cooperate with all new and old customers.

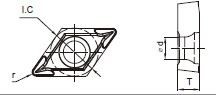

Cemented Carbide Positive Turning Insert Blanks:

Introduction:

With made in-house RTP powder, We GEHM as China leading manufacturer of premium cemented carbide insert tool blanks supply a wide range of CNC indexable positive turning insert blanks for machining different workpieces, with various specifications, chipbreakers and classical grades to select.

A positive insert has an angle of less than 90° (for example, 7° clearance angle) while a negative insert has an angle of 90° (0° clearance angle). Positive inserts are featured with single sided, low cutting forces, side clearance, and first choice for internal turning and for external turning of slender components.

Specification:

Shape | Style | Dimension (mm) | Grade | |||

IC | T | D | R | GU20 | ||

| CCMT060202 | 6.35 | 3.97 | 2.8 | 0.2 | ● |

CCMT060204 | 6.35 | 3.97 | 2.8 | 0.4 | ● | |

CCMT060208 | 6.35 | 3.97 | 2.8 | 0.8 | ● | |

CCMT09T304 | 9.53 | 3.97 | 4.4 | 0.4 | ● | |

CCMT09T308 | 9.53 | 3.97 | 4.4 | 0.8 | ● | |

CCMT120404 | 12.70 | 4.76 | 5.5 | 0.4 | ● | |

CCMT120408 | 12.70 | 4.76 | 5.5 | 0.8 | ● | |

| VCMT110304 | 6.35 | 3.18 | 2.8 | 0.4 | ● |

VCMT160404 | 9.53 | 4.76 | 4.4 | 0.4 | ● | |

VCMT160408 | 9.53 | 4.76 | 4.4 | 0.8 | ● | |

| TCMT110204 | 6.35 | 2.38 | 2.8 | 0.4 | ● |

TCMT110208 | 6.35 | 2.38 | 2.8 | 0.8 | ● | |

TCMT16T304 | 9.53 | 3.97 | 4.4 | 0.4 | ● | |

TCMT16T308 | 9.53 | 3.97 | 4.4 | 0.8 | ● | |

| DCMT11T304 | 9.53 | 3.97 | 4.4 | 0.4 | ● |

DCMT11T308 | 9.53 | 3.97 | 4.4 | 0.8 | ● | |

| DCMT070202-MV | 6.35 | 2.38 | 2.8 | 0.2 | ● |

DCMT070204-MV | 6.35 | 2.38 | 2.8 | 0.4 | ● | |

DCMT070208-MV | 6.35 | 2.38 | 2.8 | 0.8 | ● | |

DCMT11T304-MV | 9.53 | 3.97 | 4.4 | 0.4 | ● | |

DCMT11T308-MV | 9.53 | 3.97 | 4.4 | 0.8 | ||

Grade property:

GEHM Grade | Average WC Grain Size | Industry Classification | Cobalt content | Hardness | Density | TRS(N/mm2) | Recommended coating | Application | ||||

Uncoated | CVD | PVD | Turning | Milling | Grooving | |||||||

GU20 | Fine | k20-k35 | 10.30 | 91.70 | 14.40 | 3500.00 | ● | ● | ☆ | ☆ | ☆ | |

Features:

● Made in-house tungsten powder, 10k tons capacity per year

● Complex pressing capabilities

● Optimal chipbreaker design

● Press to near-net shapes

Application:

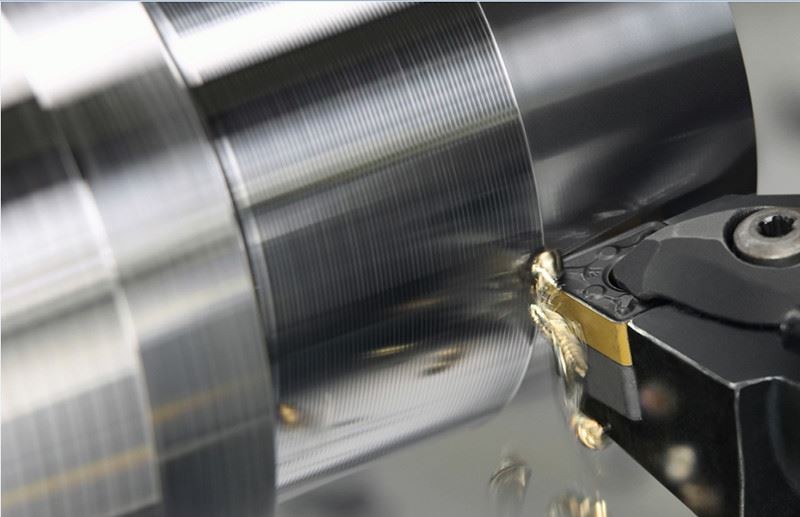

● Stainless steel machining

● Steel machining

● Internal turning and for external turning

Products:

Our Advantages:

● Over 3000+ mould available

● Lab research and samples analysis available

● HIP sintered

● Quick delivery 4~6 weeks

Our Services:

● Material inspection and approval

● Dimension inspection and approval

● Sample analysis service available

● OEM and ODM accepted

Production Process:

Our Factory:

Our Facilities:

Our Certificates:

FAQ:

Q1: What about the lead time for the mass production?

A: Honestly, it depends on the order quantity and the season you place the order.

Q2. We buy from supplier A. What is the difference between your company with supplier A?

A: We are TOP 5 manufacturer of cutting tool blanks in Asia. We have our own RTP making departs wich can offer our customers with wide choice on different grade RTP. Also we have our own mold making departs. OEM and ODM are welcome for custom-molded parts. With 4 million pcs output per month, we can promise you quickly delivery.

Q3. What’s the payment term?

A: T/T, 30% as deposit before production, balance before shipment.

Packaging & Shipping:

Our Standard and Customized Carbide Turning Inserts Solid CBN Tips has extremely strong cost performance, competitive advantages and continuous stability of product quality, therefore, it is a wise choice to choose it. We provide an inclusive work environment and treat each of our colleagues as an individual. We uphold the development concept of 'adhering to tradition and leading fashion', and constantly innovate and develop ourselves.

Hot Tags: positive turnning insert blanks, China, suppliers, manufacturers, factory, customized, industrial blade carbide materail, Cemented Carbide Wear Parts for Snow Mobile, circular saw blade supplier, Tungsten Preforms, carbide blanks flat, Bearing Ball Blank