Reputation is the soul of an enterprise and quality is the life of an enterprise. Based on the principle of 'sincere cooperation, mutual benefit and win-win', our company has made unremitting efforts to provide high-quality Cemented Carbide Taper Nibs, DNMA blanks, Crushing Sand Bar and intimate services to customers. We require our employees to think efficiently, act efficiently and pursue efficient performance. Our staff work together to promote the development of the company, so as to ensure the stability of most people.

Cemented Carbide Negative Turning Insert Blanks:

Introduction:

China leading manufacturer of premium cemented carbide tool blanks, we GEHM supply a complete range of ISO standard and custom-made CNC indexable negative turning insert blanks as sintered from made in-house RTP powder to meet different metalworking requirements, with various specifications, chipbreakers and classical grades to select.

A negative insert has an angle of 90° (0° clearance angle), while a positive insert has an angle of less than 90° (for example, 7° clearance angle). Negative inserts are featured with double and/or single sided, high edge strength, zero clearance, first choice for external turning and heavy cutting conditions.

Specification:

Shape | Style | Dimension (mm) | Grade | |||

IC | T | D | R | GK05 | ||

| CNMG120404-HJ | 12.70 | 4.76 | 5.16 | 0.4 | ● |

CNMG120408-HJ | 12.70 | 4.76 | 5.16 | 0.8 | ● | |

CNMG120412-HJ | 12.70 | 4.76 | 5.16 | 1.2 | ● | |

| TNMG160404-HJ | 9.53 | 4.76 | 3.81 | 0.4 | |

TNMG160408-HJ | 9.53 | 4.76 | 3.81 | 0.8 | ● | |

TNMG160412-HJ | 9.53 | 4.76 | 3.81 | 1.2 | ● | |

TNMG220408-HJ | 12.70 | 4.76 | 5.16 | 0.8 | ||

TNMG220412-HJ | 12.70 | 4.76 | 5.16 | 1.2 | ||

TNMG220416-HJ | 12.70 | 4.76 | 5.16 | 1.6 | ||

| WNMG080404-HJ | 12.70 | 4.76 | 5.16 | 0.4 | ● |

WNMG080408-HJ | 12.70 | 4.76 | 5.16 | 0.8 | ● | |

WNMG080412-HJ | 12.70 | 4.76 | 5.16 | 1.2 | ● | |

| SNMG120404-HJ | 12.70 | 4.76 | 5.16 | 0.8 | |

SNMG120408-HJ | 12.70 | 4.76 | 5.16 | 1.2 | ● | |

SNMG120412-HJ | 12.70 | 4.76 | 5.16 | 1.6 | ● | |

Grade property:

Class | Grade | Chemical Composition(%) | Physical Characteristics | Applicable Coating | Application | ||||||

WC | Co | Other | Hardness(HRA) | Density(g/cm3) | TRS | None | PVD | CVD | |||

K | GK05 | 93.90 | 6.00 | 0.10 | 91.9 | 14.9 | 2720 | ◎ | ◎ | Suitable for general purpose machining of | |

GU10 | 93.29 | 6.10 | 0.61 | 93.0 | 14.8 | 2700 | ◎ | ◎ | Suitable for heat-resistant steel and alloy steel | ||

GU20 | 89.10 | 10.30 | 0.60 | 91.6 | 14.4 | 3500 | ○ | ◎ | Fine grain material. Suitable for general | ||

GU25UF | 86.70 | 12.00 | 1.30 | 92.6 | 14.1 | 4200 | ○ | ◎ | Ultra-fine grain material. Suitable for finish | ||

P | GP15G | 89.80 | 6.00 | 4.20 | 91.5 | 14.2 | 2300 | ◎ | Suitable for finish machining of steel and | ||

GP25G | 88.71 | 7.90 | 3.39 | 90.5 | 14.1 | 2300 | ◎ | Suitable for semi-finish and slightly rough | |||

GP35G | 86.35 | 10.00 | 3.65 | 89.5 | 14.0 | 2500 | ◎ | Suitable for rough, semi-finish machining of | |||

M | GM15 | 88.00 | 10.50 | 1.50 | 91.8 | 14.3 | 2700 | ○ | ◎ | e for semi-finish and finish machining | |

GM25 | 89.20 | 9.20 | 1.60 | 90.7 | 14.4 | 2500 | ◎ | ○ | Suitable for rough, semi-finish and finish | ||

Features:

● In-house powder plant with annual production capacity 10k tons

● Chip control and process security

● Excellent surface finish machined by coated inserts

● Minimum grind stock to save grinding cost

Application:

● Cast iron machining

● Steel machining

● Stainless steel machining

● Roughing to finishing

Products:

Our Advantages:

● Material expertise for demanding challenges

● Europe high-end pressing machines equipped

● Multi-axial press capabilities

● Annual production capacity for insert blanks reaches 50 million pcs

Our Services:

● Material inspection and approval

● Dimension inspection and approval

● Sample analysis service available

● OEM and ODM accepted

Production Process:

Our Factory:

Our Facilities:

Our Certificates:

FAQ:

Q1. What countries do you mainly export?

A: America is our main export market at present. Our custom-molded insets blanks and saw tips sell well there. And we also have business in Asia and Europe. Europe is a market with unlimited potential and it is also our focus of works for the long future. This is also the main purpose of our exhibition. We want to show our strength and our sincerity to the European toolmakers. It is our hope to promote, by joint efforts, both trade and friendship to our mutual advantage.

Q2. Do you have customers in XXX country? Who?

A: Yes, we do have customers in XXX country. But I am afraid that I am not allowed to offer you our client's name. We have a NDA with our customers. We have the obligation to protect their information security.

Q3. What certification do you have?

A: We are ISO quality and environment certified, ISO9001 and ISO14001.

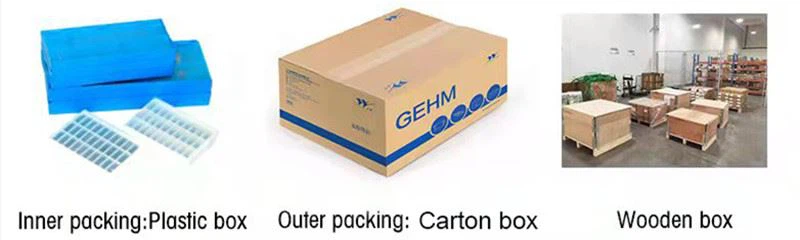

Packaging & Shipping:

For many years, our company has been committed to the research and manufacture of Solid Carbide Saw Blanks. Relying on continuous innovation and improvement, we enjoy a high reputation in the industry. We adopt advanced processing technology, keep a close eye on international manufacturing standards, and complete every detail of product production with high quality and high efficiency. Our company takes the customer demand as the guidance, strives for the survival by the quality prestige. We actively cooperate with customers, do well in after-sales service, and provide high-level services to customers on the principle of 'active cooperation, common progress and win-win'.

Hot Tags: negative turnning insert blanks, China, suppliers, manufacturers, factory, customized, Cemented Carbide Nozzles, Drawing Dies, durable saw tips, Carbide Rings, circular saw blank, Wire Drawing Die Alignment Wheel