Our meticulous and comprehensive service is also an important condition to ensure the quality of our Cemented Carbide for Stamping, Gear Sticks, carbite strip. Our company is based on the evaluation of contract bidding documents to ensure the effective implementation of the quality assurance certificate. We adhere to the business philosophy of 'integrity as the purpose and quality as the backing'. Sincerely welcome new and old friends to call, write, and negotiate business! All personnel of our company must receive strict pre job training and have strict production progress and product quality monitoring system.

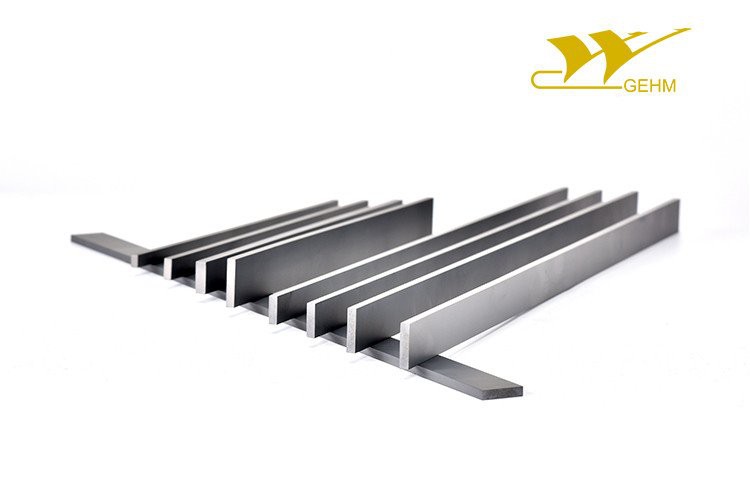

Carbide flat bars for Metalworking:

Product Introduction:

Tungsten carbide flat bars are mainly made from wolfram carbide and cobalt powder by powder metallurgy methods. The main production process of tungsten carbide bar stock is powder milling, ball milling, pressing and sintering. For different uses, the content of WC and Co in tungsten carbide square bar is not the same. Solid carbide rectangular bar is mainly used to process gray cast iron, non-ferrous metal materials, chilled cast iron, hardened steel, PCB, brake materials, etc. Carbide flat bar can be further processed at clients’ factory or workshop by wire cut, grinding, soldering.

Product feature and application:

● GU20 is the first choice in most cases. It can be used to all materials.

● GK05 is suitable for turning and milling of cast iron, non-ferrous metals.

Product Details:

Shape | Style | Dimension(mm) | Grade | |||||

L | W | T | GK05 | GU20 | GU10 | GK30H | ||

| KG01330024 | 330 | 4 | 2 | ● | ● | ||

KG01330025 | 330 | 5 | 2 | ● | ● | |||

KG01330026 | 330 | 6 | 2 | ● | ● | |||

KG01330027 | 330 | 8 | 2 | ● | ● | |||

KG01330028 | 330 | 10 | 2 | ● | ● | |||

KG01330029 | 330 | 12 | 2 | ● | ● | |||

KG01330030 | 330 | 14 | 2 | ● | ● | |||

KG01330031 | 330 | 15 | 2 | ● | ● | |||

KG01330032 | 330 | 16 | 2 | ● | ● | |||

KG01330033 | 330 | 18 | 2 | ● | ● | |||

KG01330034 | 330 | 20 | 2 | ● | ● | |||

KG01330035 | 330 | 22 | 2 | ● | ● | |||

KG01330036 | 330 | 25 | 2 | ● | ● | |||

KG01330037 | 330 | 30 | 2 | ● | ● | |||

KG01330038 | 330 | 4 | 3 | ● | ● | |||

KG01330039 | 330 | 5 | 3 | ● | ● | |||

KG01330040 | 330 | 6 | 3 | ● | ● | |||

KG01330041 | 330 | 8 | 3 | ● | ● | |||

KG01330042 | 330 | 10 | 3 | ● | ● | |||

KG01330043 | 330 | 12 | 3 | ● | ● | |||

Carbide flat bars for Metalworking applications:

Production Process of carbide square blanks:

GEHM Facilities:

GEHM Certification:

Our Factory for carbide flat bars for Metalworking:

GEHM attended cutting tool related shows in China and abroad:

Package and inspection of carbide flat bars for Metalworking:

Our Advantages:

● 30 Days delivery on standard carbide flats / strips

● Multi grades for different application & machining.

● Preformed carbide flats for special usage.

● Free sample analysis, and multiple grade offering

● Multiple grades carbide flat bars in different type and dimensions for Metalworking industry

FAQ:

Q1: Why choose GEHM not others?

A: Unlike most of other carbide company in the world, GEHM has full carbide industry chain from APT to tungsten powder / carbide tungsten powder, RTP and sintered blanks. Our quality traceable from APT to carbide blanks. We only use self-produced 100% virgin raw material to ensure high quality. With powder & tooling made in-house, our delivery is fast & stable than many of world rivals. Clients are free to choose GEHM or other suppliers, but the facts will tell, GEHM is one of the best choice.

Q2: Grades and Tooling sharing

A: Different grades have different shrinkage rate, thus it may require different tooling for different grade. We will review case by case.

Q3: What is the normal lead time?

A: With more than 3000 sets of toolings, our normal delivery is within 30 days.

Q4: What information do I need to offer when I have an enquiry?

A: Please kindly send us the size with tolerances, grade and monthly and yearly demands.

Q5: What certification do you have?

A: We are ISO quality and environment certified, ISO9001 and ISO14001.

Q6: What’s the payment term?

A: T/T, 30% ~50% as deposit before production, balances before shipment.

Q7: How many people in the R&D department?

A: There are 12 persons in our R&D department with doctorate, master or bachelor degrees.

Q8: How many people in QC team? What kind of QC check?

A: Dimension and material will be inspected prior to and after production, GEHM have twenties specialized controller from Powder to Carbides..

Q9: How do you make QC control? Inside or third party?

A: Usually, we do the QC control in house. If you need, third party like SGS report could be provided.

Q10: What is the warranty?

A:We can issue material certificate upon delivery. If there is any discrepancy on quantity/weight, please let us know within 2 weeks after arrival of the goods. If there is any quality discrepancy, please send us the report with 4 weeks. Thanks.

Q11: How do you deal with customer’s complaint?

A: We will use 8D process to deal with customer’s complaint.

Packaging & Shipping:

We pursue excellence, strive for perfection in every one of your products, be meticulous and provide you with the best Sintered Tungsten Cemented Carbide Flat Bar for Tool Parts Steel Per Kg Price. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We also have the strong ability of integration to supply our best service, and plan to build the warehouse in the different countries around the world, that will be more conveniently to service our customers.

Hot Tags: carbide flat bars for metalworking, China, suppliers, manufacturers, factory, customized, Inserts blanks sintered for fabricator, EDM Blocks, apkt 16 insert, Turnning Insert Blanks for Cast Iron, Threaded Nozzle for PDC, Crushing Sand Bar