The company has gradually developed into one of the largest and most powerful enterprises in the Tungsten Carbdie Wire Drawing Die, Sand Making Bar, carbide preform blanks industry. Our advantages include competitive salary and benefits, advanced and standardized management system, advanced office environment and factory facilities, broad development prospects and room for advancement, and humanized corporate culture. We will insist on professional, sincere, high quality and efficient service for our customers, constantly pursue service innovation, highlight service characteristics, establish a core team to develop together with the enterprise, and strive for strong support from the community. We strive to create a unique corporate culture and business purpose. We have established a professional and strict quality management system and perfect customer service system, so as to win the trust of global customers with high-quality products and excellent service.

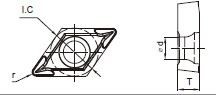

Cemented Carbide Positive Turning Insert Blanks:

Introduction:

With made in-house RTP powder, We GEHM as China leading manufacturer of premium cemented carbide insert tool blanks supply a wide range of CNC indexable positive turning insert blanks for machining different workpieces, with various specifications, chipbreakers and classical grades to select.

A positive insert has an angle of less than 90° (for example, 7° clearance angle) while a negative insert has an angle of 90° (0° clearance angle). Positive inserts are featured with single sided, low cutting forces, side clearance, and first choice for internal turning and for external turning of slender components.

Specification:

Shape | Style | Dimension (mm) | Grade | |||

IC | T | D | R | GU20 | ||

| CCMT060202 | 6.35 | 3.97 | 2.8 | 0.2 | ● |

CCMT060204 | 6.35 | 3.97 | 2.8 | 0.4 | ● | |

CCMT060208 | 6.35 | 3.97 | 2.8 | 0.8 | ● | |

CCMT09T304 | 9.53 | 3.97 | 4.4 | 0.4 | ● | |

CCMT09T308 | 9.53 | 3.97 | 4.4 | 0.8 | ● | |

CCMT120404 | 12.70 | 4.76 | 5.5 | 0.4 | ● | |

CCMT120408 | 12.70 | 4.76 | 5.5 | 0.8 | ● | |

| VCMT110304 | 6.35 | 3.18 | 2.8 | 0.4 | ● |

VCMT160404 | 9.53 | 4.76 | 4.4 | 0.4 | ● | |

VCMT160408 | 9.53 | 4.76 | 4.4 | 0.8 | ● | |

| TCMT110204 | 6.35 | 2.38 | 2.8 | 0.4 | ● |

TCMT110208 | 6.35 | 2.38 | 2.8 | 0.8 | ● | |

TCMT16T304 | 9.53 | 3.97 | 4.4 | 0.4 | ● | |

TCMT16T308 | 9.53 | 3.97 | 4.4 | 0.8 | ● | |

| DCMT11T304 | 9.53 | 3.97 | 4.4 | 0.4 | ● |

DCMT11T308 | 9.53 | 3.97 | 4.4 | 0.8 | ● | |

| DCMT070202-MV | 6.35 | 2.38 | 2.8 | 0.2 | ● |

DCMT070204-MV | 6.35 | 2.38 | 2.8 | 0.4 | ● | |

DCMT070208-MV | 6.35 | 2.38 | 2.8 | 0.8 | ● | |

DCMT11T304-MV | 9.53 | 3.97 | 4.4 | 0.4 | ● | |

DCMT11T308-MV | 9.53 | 3.97 | 4.4 | 0.8 | ||

Grade property:

GEHM Grade | Average WC Grain Size | Industry Classification | Cobalt content | Hardness | Density | TRS(N/mm2) | Recommended coating | Application | ||||

Uncoated | CVD | PVD | Turning | Milling | Grooving | |||||||

GU20 | Fine | k20-k35 | 10.30 | 91.70 | 14.40 | 3500.00 | ● | ● | ☆ | ☆ | ☆ | |

Features:

● Made in-house tungsten powder, 10k tons capacity per year

● Complex pressing capabilities

● Optimal chipbreaker design

● Press to near-net shapes

Application:

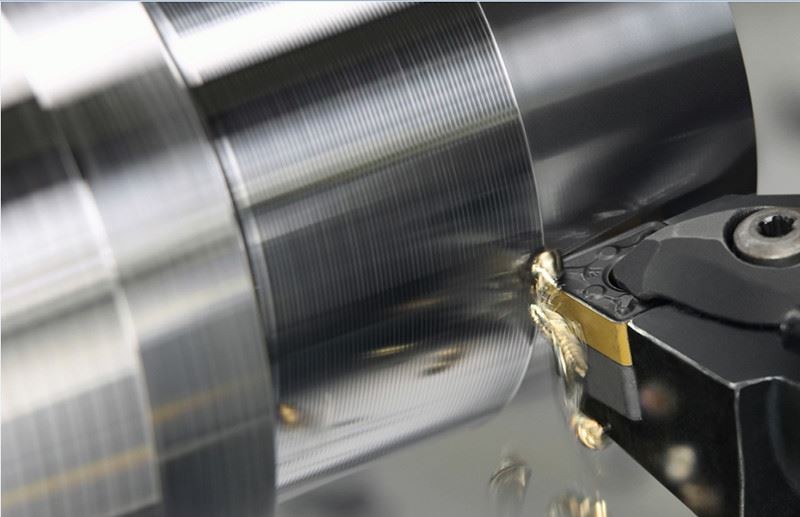

● Stainless steel machining

● Steel machining

● Internal turning and for external turning

Products:

Our Advantages:

● Over 3000+ mould available

● Lab research and samples analysis available

● HIP sintered

● Quick delivery 4~6 weeks

Our Services:

● Material inspection and approval

● Dimension inspection and approval

● Sample analysis service available

● OEM and ODM accepted

Production Process:

Our Factory:

Our Facilities:

Our Certificates:

FAQ:

Q1: What about the lead time for the mass production?

A: Honestly, it depends on the order quantity and the season you place the order.

Q2. We buy from supplier A. What is the difference between your company with supplier A?

A: We are TOP 5 manufacturer of cutting tool blanks in Asia. We have our own RTP making departs wich can offer our customers with wide choice on different grade RTP. Also we have our own mold making departs. OEM and ODM are welcome for custom-molded parts. With 4 million pcs output per month, we can promise you quickly delivery.

Q3. What’s the payment term?

A: T/T, 30% as deposit before production, balance before shipment.

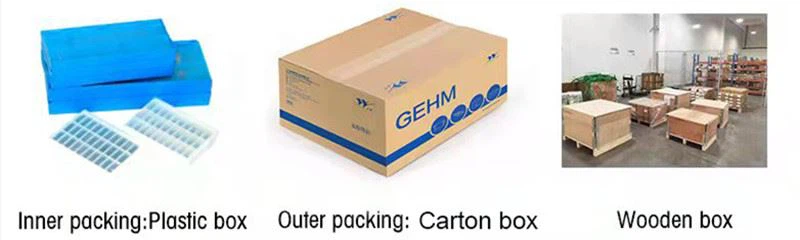

Packaging & Shipping:

Our mission is to let innovation inject the soul into product design and allow the Carbide Insert Ccmt09t304/08 for Cutting Steel to create greater value for customers. We introduced advanced automated production lines from Germany and Italy, and explored digital and intelligent upgrade of factory manufacturing, and extended production from large-scale manufacturing to personalized customization, and gradually formed a good development trend of one-key production, precision quality, coordinated development, and efficient distribution. Since its establishment, the company has always adhered to the people-oriented concept of sustainable development, created an atmosphere that respects and gathers talents, and pays attention to the harmonious development of employees and the company.

Hot Tags: positive turnning insert blanks, China, suppliers, manufacturers, factory, customized, Tungsten Preforms, EDM Blocks for Stamping Silicon Steel Sheet, Carbide for Construction, EDM Blanks, Tungsten Carbide Rings, TNMG Insert Tools