Our carbide inserts blanks, Cemented Carbide Valve Ball, Parting Insert Blanks is standard product with high stability for long and continuous use in harsh environments. We have the sincerity and enthusiasm to run the company, and partners with development vision to move forward together, to provide careful service and support for partners and investors. Through multi-directional and multi-form external exchanges, we effectively develop resource potential, improve the quality of talent resources, and provide talent guarantee for sustainable development of the enterprise. We strive to create a development platform for our employees, so that they can fully practice in their positions and freely choose to develop in multiple career paths such as operation, management and professional technology to achieve self-worth enhancement.

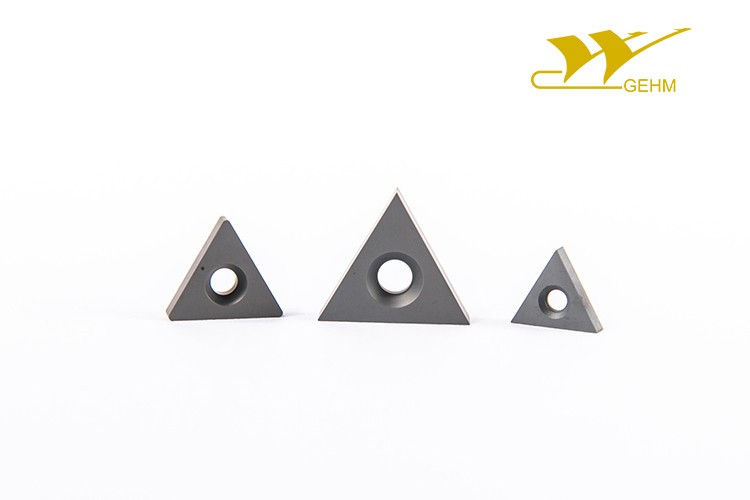

Cemented Carbide Threading Insert Blanks:

Introduction:

As China leading manufacturer of premium cemented carbide turning insert blanks, we GEHM supply a wide range of CNC indexable threading insert blanks from made in-house RTP powder for machining different thread types, to meet and exceed the rigorous standards and tolerances set by the oil and gas, automotive, medical and aerospace industries.

Threading inserts are indexable or rotatable cutting tools that are held by a special tool and used for creating various thread types and sizes in workpiece. Carbide threading inserts are the most common material type, as they allow for higher cutting speeds than tool steel and can retain a sharper cutting edge.

Specification:

Shape | Style | Dimension (mm) | Grade | ||||

IC | T | D | R | GU20 | GU20F | ||

| TNLW11034 | 6.35 | 3.18 | 3.00 | 0.4 | ● | ○ |

TNLW16034 | 9.525 | 3.18 | 4.00 | 0.4 | ● | ○ | |

TNLW220408 | 12.70 | 4.76 | 4.85 | 0.8 | ● | ○ | |

| TNXC160302 | 9.525 | 3.18 | 3.89 | 0.2 | ● | ○ |

TNXC160402 | 9.53 | 4.76 | 3.89 | 0.2 | ● | ○ | |

TNXC220402 | 12.700 | 4.76 | 5.16 | 0.2 | ● | ○ | |

TNXC270602 | 15.88 | 6.35 | 6.40 | 0.2 | ● | ○ | |

Grade property:

GEHM Grade | Average WC Grain Size | Industry Classification | Cobalt content | Hardness | Density | TRS(N/mm2) | Recommended coating | Application | ||||

Uncoated | CVD | PVD | Turning | Milling | Grooving | |||||||

GU20 | Fine | k20-k35 | 10.30 | 91.70 | 14.40 | 3500.00 | ● | ● | ☆ | ☆ | ☆ | |

GU20F | Ultra Fine | K15-K25 | 10.30 | 92.10 | 14.38 | 3800.00 | ● | ● | ☆ | ☆ | ☆ | |

Features:

● 100% virgin raw material

● High product consistency

● Optimal chipbreaker design

● Supreme cutting performance

● Long tool life

Application:

● Internal threading

● External threading

● Thread milling

Products:

Our Advantages:

● Material expertise for demanding challenges

● From lab research to batch production

● Multi-axial press capabilities

● All mould made in-house

● HIP sintered

● Quick delivery 4~6 weeks

Our Services:

● Material inspection and approval

● Dimension inspection and approval

● Sample analysis service available

● OEM and ODM accepted

Production Process:

Our Factory:

Our Facilities:

Our Certificates:

FAQ:

Q1. Would you send a catalog & pricelist with all the items you have available tooling for?

A: Leave your contact info and we'll send asap.

Q2. What kind of cutting tool can you provide?

A: We mainly produce sintered blanks for inserts, flats, circular saw.

Q3. What’s the main industry does your production aim at?

A: The key industries include aerospace, automotive, oil & gas, mining and woodworking.

Q4. Can you show me your production flow?

A: Pressing to sintering.

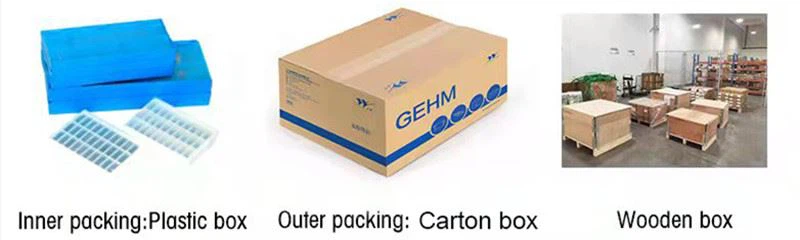

Packaging & Shipping:

We actively develop innovative • Double Disc Grinding and solutions that meet our customers' needs, and inject new vitality into the transformation and upgrading of industries. Our corporate culture construction is people-oriented. Our company attaches great importance to talent strategy in order to continuously improve the competitiveness of enterprises in the fierce competition. We continue to innovate our business model to achieve leapfrog development.

Hot Tags: carbide threading insert blanks, China, suppliers, manufacturers, factory, customized, Cemented Carbide for Stamping, Tungsten Carbide Flat, mold inserts carbide supplier, Carbide Wire Drawing Die, thread mill cutter insert, Cemented Carbide Preforms